This additiona process would require new equipment onsite to process the gas into hydrogen and filling stations to safely transfer the hydrogen ready for transport. This would not represent a significant change in noise or air pollution from the existing equipment.

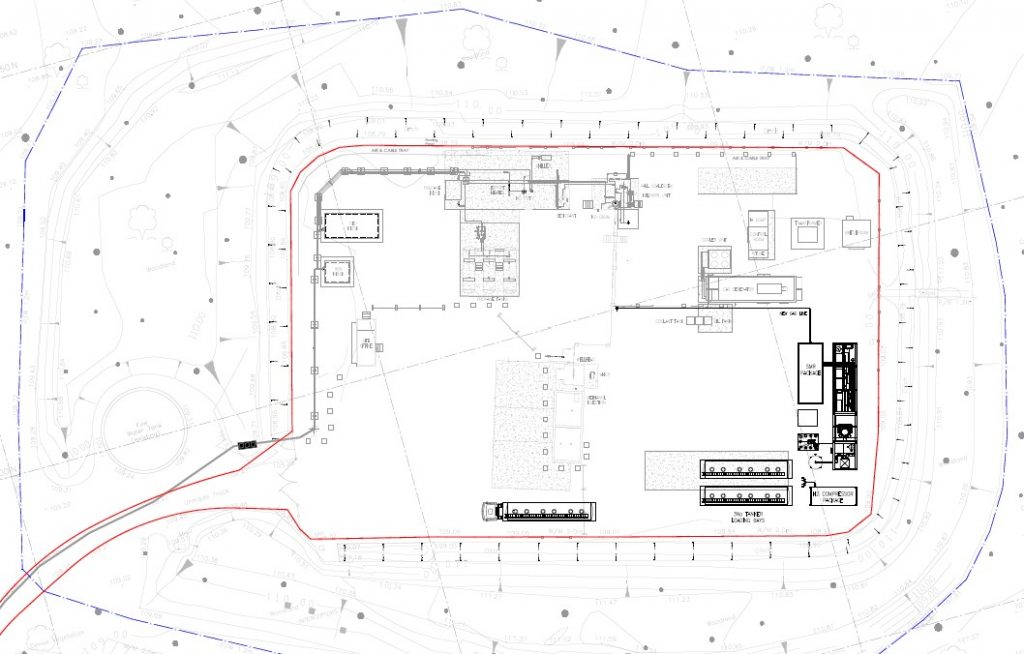

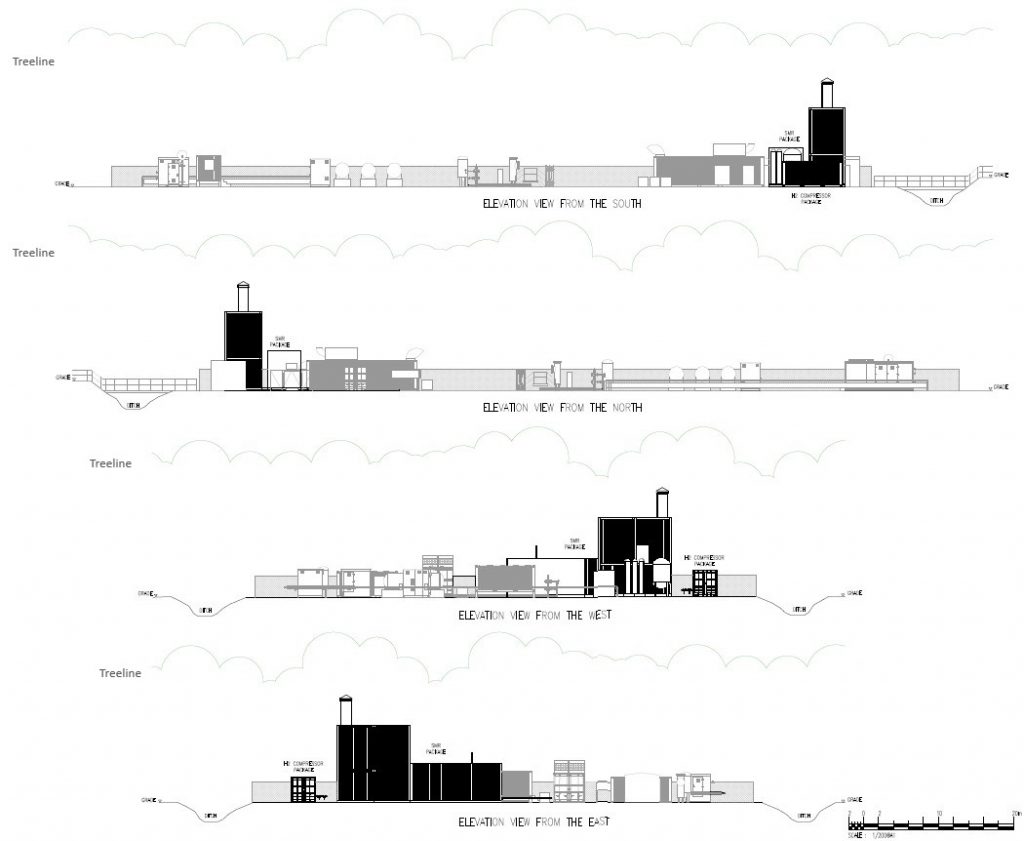

This new equipment would be contained within the existing fenced compound, which is also screened by trees reaching as high as 25 m, thereby further reducing the potential for visual impact as viewed from the wider area.

The number of HGV movements to and from the site would naturally increase for a short period during installation. However, once operational, movements will be associated with the transportation of hydrogen off the site and for periodic maintenance c.up to four HGVs and four light goods vehicles per day. These levels are similar to those proposed with historic traffic management plans for other schemes at the site and, it is not considered that the proposal would have any impact on the highway network or on general environmental amenity.